MAKE A MEME

View Large Image

| View Original: | Stetefeldt roasting furnace.png (949x773) | |||

| Download: | Original | Medium | Small | Thumb |

| Courtesy of: | commons.wikimedia.org | More Like This | ||

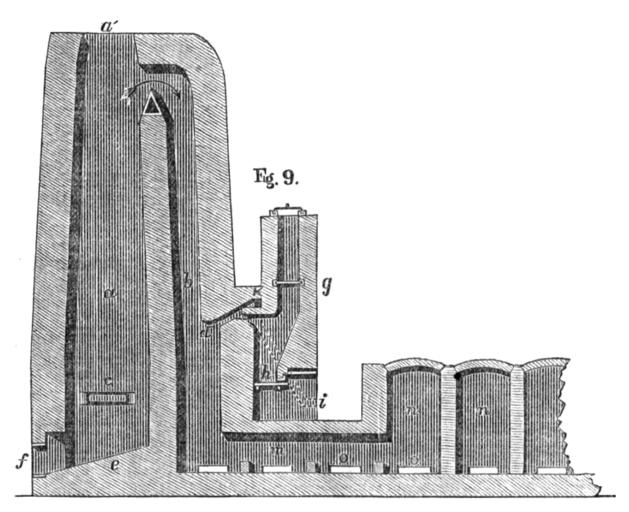

| Keywords: Stetefeldt roasting furnace.png fr Four à griller les minerais d'argent ou d'or de Carl August Stetefeldt ou Charles A Stetefeldt fr Roasting kiln by Carl August Stetefeldt also Charles A Stetefeldt design to roast gold and silver ores Text Appearing Before Image <br> Stetefeldt's Roasting Furnace This furnace now being built at Austin Nevada is represented in Fig 9 showing a vertical cross section The furnace at Reno Nevada has a dust-chamber in place of the flue b of Fig 9 the omission of Text Appearing After Image <br> which simplifies the construction without injury to the good results of roasting The furnace has three important departments 1st The roasting shaft a twenty-five feet high and five feet wide at the bottom narrowing somewhat toward the top to prevent the adherence of dust to the wall It is a simple shaft of common bricks built as smooth as possible On the top of the shaft at a' is placed an iron feeder through which a permanent and uniform feeding of the pulverized ore already mixed with salt is effected The ore falls on the bottom e and when half a ton or a ton is accumulated it is drawn out through the door f 2d The fire-places There are three gas generators constructed similarly to that of the copper-refining furnace at Mansfield Prussia The cover is taken off and the charcoal introduced The cover is placed again on its frame which contains sand in a groove in order to shut off the draft entirely The slide door near g is drawn out and the charcoal falls on the grate h through which as much air is admitted as is necessary There are also two canals on each side of the grate one of which is shown by dotted lines i both communicating at k Through these canals is regulated the admission of the air for oxidizing or burning the carbonic acid created above the grate h In the flue d air and gas meet together and the burning product heats the furnace Two of these generators heat the shaft a ; the mouth of one is shown in the drawing by c the other is on the opposite side and therefore not visible in the plan The two generators are constructed exactly like g with the exception that the flue d is not inclined but horizontal The flue d as well as the generators above the grates are lined with fire-bricks 3d The dust-chambers With the draft the gases from the shaft with a part of the fine ore dust pass through the vertical flue b then through the horizontal one m into a series of chambers i of different sizes The first four chambers n are smaller than the four following which are not represented in the diagram ; from the last chamber the gases draw into the chimney The dust can be removed from the bottom of the chambers through the doors o o Almost all the dust is regained and not in a raw condition as from dust-chambers of reverberatory furnaces requiring re-roasting but perfectly chloridized which is principally due to the auxiliary generator g y and the longer contact with the chlorine gases 1870 https //archive org/details/roastingofgoldsi00ksrich Roasting of gold and silver ores and the extraction of their respective metals without quicksilver p 100 Guido Küstel 1817-1882 other versions PD-old-70-1923 Roasting kilns | ||||